|

Requirements of RoHS

|

|

Rich-Tech refers to 2011/65/EU Appendix II to define RoHS

Cd less than 100mg/kg

Pb less than 1000mg/kg

Hg less than 1000mg/kg

Cr(VI) less than 1000mg/kg

Total PBBs (polybrominated biphenyl) less than 1000mg/kg

Total PBDEs (polybrominated diphenyl ethers) less than 1000mg/kg

|

|

Non0halogen requirement

|

|

Rich-Tech refers to IEC 61249-2-21 to define non-halogen

Total Cl less than 900ppm

Total Br less than 900ppm

Total halogen Cl+Br could not surpass 1500ppm

|

|

Requirements of REACH |

|

Rich-Tech refers to (EC)No 1907/2006(REACH) 161种161 kinds of SVHC concentration less than 0.1%(w/w)

|

|

||||||||||||||

Environmental protection, health and security policy of Rich-Tech

Implementing company policy in every manufacturing step as well as procedure

Innovations in sustainable development

Clients of Rich-Tech and world top host manufacturing enterprises would demand more and more innovation to meet the need of sustainable development of the industry. They would help to form the independent development of industrial technology, such as some renewable and replaceable energy resources and advanced recycling techniques.

We constantly push our institutions to find a more environmental way to enhance the performance and efficiency of our product and solution.

The primary goal of Rich-Tech in the innovation of sustainable development is to be able to balance enterprise cost with environmental protection. First, these clients would directly benefit from the fine production capability adopting sustainable development solution. Second, the whole society and human kind would also benefit from the environmental protection of manufacturers like Rich-Tech.

Heat emission

Rich-Tech is actively developing product with low consumption material and promoting materials like PR4A AND PR4S in areas like LED lighting, electric automobile and solar inverter to lower heat consumption and enhance product performance.

Rich-Tech is actively developing product with low consumption material and promoting materials like PR4A AND PR4S in areas like LED lighting, electric automobile and solar inverter to lower heat consumption and enhance product performance.

EU REACH Project

EU has adopted the regulation of 1907/2006/EC (REACH), a strict supervision regulation enacted for the supervision of registration, evaluation and auditing and authorized production of chemicals. REACH regulation is a strictly standardized management regime intended for standardizing registration, evaluation and auditing and authorized production of chemicals, and it formed a behavior obligation for the manufacturer, importer and the low-stream consumers in EU whose yearly total volume of chemical production has surpassed one ton. Only after the registration in the European Chemical Administration could one be granted to use EU/EEA. To fully implement REACH regulation, we have made the following preparations:

1,Rich-Tech is the low-stream consumer of chemicals and has full understood the impact and influence REACH regulation had on magnetic material industry. After communicating with upper-and-lower stream enterprises, especially EU clients, the company has collected the data and information required for the registration in accordance with the regulation.

2,Rich-Tech strives to manufacture in accordance with international standards or the real product standards of world famous enterprises, strengthening testing technology and methods, and working hard to get mutual acknowledgement with EU test data.

3,Rich-Tech has checked all its internal chemicals and reclassified them in accordance with the requirements of REACH regulation.

4,Rich-Tech is actively working on the research of substitution material. Under the premises of insuring product performance, reduce the use of potentially dangerous chemical materials in the product, so as to reduce the negative influence and impact the product has towards the environment and enhance its international competitiveness.

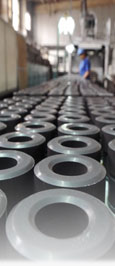

Reuse of wasted water

In the past years, Rich-Tech has put great investment in the recycle of industrial water. And mainly during the grinding of magnetic core does it require large volume of water. After installing four latest closed circuits for the recycle and cooling of industrial water, the company could save up to 2 million cubic meter of water each year.

Improve waste management

To fully reduce the waste of raw materials, Rich-Tech has established a core team of equipment management based on the 5S management method, revising the recycle procedure so as to insure that the waste could recycle to the recycle center (recycle volume has increased 20%).